Why do we need Boiler Treatment and Maintenance

Posted by SEBASTIAN ZOTA

Spring is almost here. It’s time to consider how your boiler system will spend the next few months while it sits dormant. Where should you start? Alternative Heating & Supply recommends that you begin with Boiler treatment and maintenance.

What is Boiler Treatment and why do we need it?

A complete water treatment program for a boiler will usually include a chemical oxygen scavenger, alkalinity builder and polymer sludge conditioner and, depending on the application, may also include phosphate treatment and a condensate line treatment.

Wood Boiler Manufacturer programs insist the wood boiler owner meet certain nitrite levels in order to comply with warranty requirements in regards to boiler corrosion protection.

Adding a boiler water treatment to your wood boiler you will be protecting your investment, and our wood boilers are an investment. They provide us heat, save us money and make us self-sufficient so why not do the best we can to protect it with proper treatment and maintenance. A poorly maintained boiler system can lead to scaling, corrosion, sludge buildup, harmful impurities, which in turn could lead to a complete system shutdown. So save yourself the time and trouble of costly downtimes, expensive maintenance and extend the life of your wood boiler just by doing some simple maintenance. Changing your water in your boiler every year and adding boiler treatment. Bottom line saving pennies by not adding boiler treatment today could cost big money later!

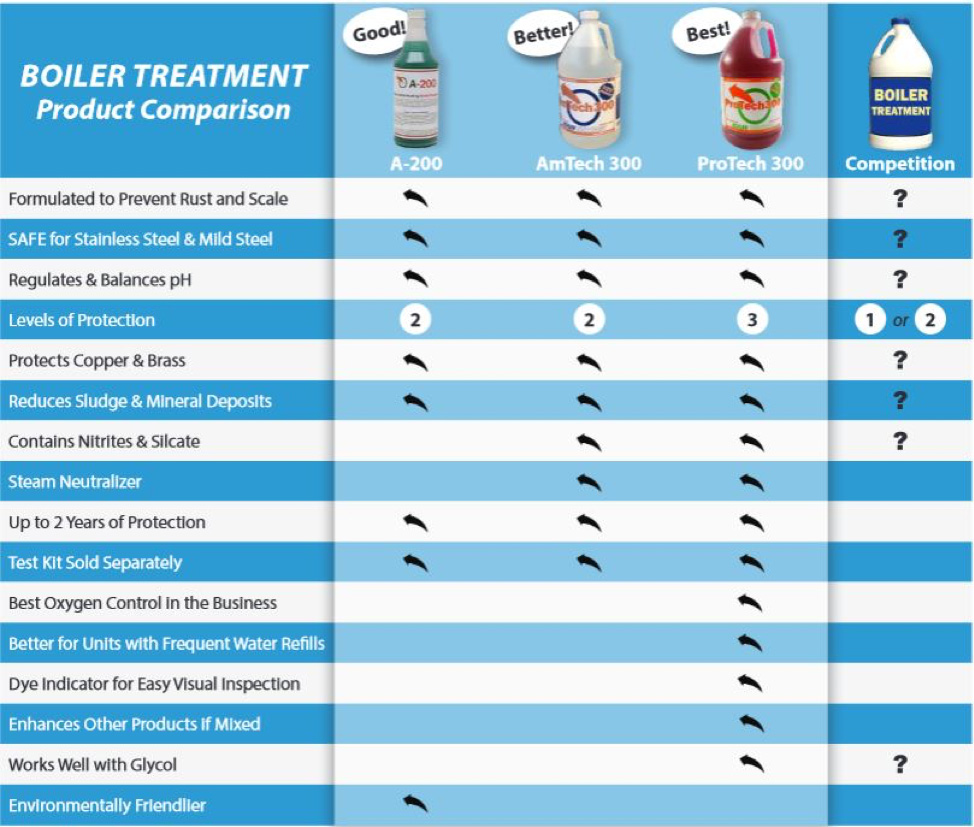

There are all kinds of boiler treatments out there, which can be confusing at times. Most will other these boiler treatments protect against corrosion and rust. The average boiler treatment only has 2 levels of protection and only 2 active ingredients.

What’s the difference between Alternative Heating & Supply’s Boiler treatments and the competitors?

For starters – All of our boiler treatments meet or exceed all Manufacturers Boiler Treatment Nitrite Warranty requirements. They promote an internal chemical balance and a healthy environment for wood boilers. Secondly, Our Protech 300 provides the highest level of protection.

Our top of the line boiler treatment is The ProTech300. We have taken it to the next level. It has the highest level of protection for the wood boiler. It has 3 levels of protection with 3 active ingredients in it. The ProTech 300 is a new and improved formula with chemical detection technology. The 3 Protection “Levels”

- Nitrite

- Phosphonate

- Anodic inhibitor

ProTech 300 Boiler Water Treatment has been designed to be used in Manufacturers boiler treatment programs.

ProTech300 at a Quick Glance

- Protects your wood boiler from rust, corrosion, and scale

- Meets or exceeds all boiler manufacturer nitrite warranty requirements.

- Balances pH and Alkalinity confidently

- Each one-gallon bottle treats 300 Gallons at 1500 PPM

- Works with Stainless Steel, Mild Steel and Boiler Plate

- Protects copper & brass.

- Perfect for closed loop systems, hot water systems, steam boilers, wood burning boilers

- Has Dye Indicator for easy Visual Inspection.

- Enhances Other Products if mixed.

- Works well with Glycol.

- Provides the best oxygen control in the business.

For our money savvy friends, we offer AmTech300 that works just as well as any other name brand boiler treatments that come directly from the manufacturers like Wood Master or Central Boiler. AmTech300 offers 2 levels of protection- 2 Active Ingredients like all the other competitive brands out there. See Comparison Chart for easy viewing of the differences.

AmTech300 at a Glance

Protects your wood boiler from rust, corrosion, and scale

Balance pH and Alkalinity

- One Gallon treats up to 300 gallons

- Works with all Wood Boilers

- Protects From Rust & Scale

- Works with Mild Steel and Stainless Steel

- Flush Annually for Best Protection

For our ECO (Planet) friendly friends we also offer an Environmentally Friendly Boiler Treatment- The A200. It is specifically designed for outdoor and indoor wood boilers. This product may also be used as a full spectrum water conditioning agent for other hydronic and solar heating applications. The A200 is Nitrate based instead of Nitrite, which makes it safer for the environment. See the Comparison Chart for easy viewing of the differences.

A200 at a Glance

- Can be used on outdoor & indoor wood boilers with mild or stainless-steel construction.

- Can also be used as water conditioning agent for other hydronic and solar heating applications.

- Corrosion and scale inhibitor for wood burning stoves

- One quart treats 200 gallons.

- A200 is the only environmentally friendly boiler treatment.

- Nitrate based instead of Nitrite