Product Description

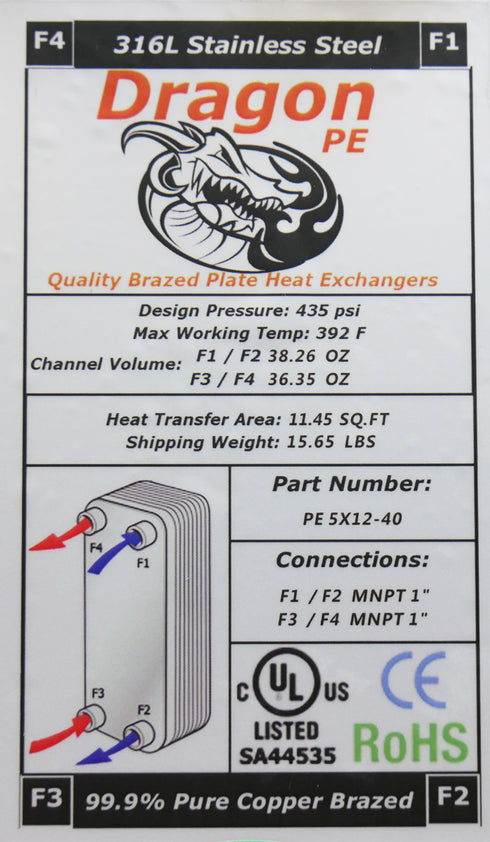

Dragon Brazed Plate Heat Exchanger, 5x12- 40 Plate Water to Water Heat Exchanger 75,000 BTU, 1" MPT

• Designed specifically for Open Loop & Wood Boiler Applications

• Thicker Gauge 316L Stainless Steel and Plates further apart to prevent clotting

• Smooth sides Tell you the plate Exchanger is brazed and Pressed for longer life.

• BTU Rating: 75,000 (Commonly used for heating 2500 to 3,000 well-insulated homes) If the home is not well insulated add 10 to 20 plates to compensate for efficiency.

• BTU Rating is based on 10 GPM; 180F water

• High Quality, 40% Heavier then Competition, Built for Maximum Performance and Longevity

NEW! DRAGON Plate Heater Exchangers! Check it out! We designed water to water plate heat exchanger specifically for Wood Boiler Applications. All plate heat exchangers look similar on the outside. The difference lies inside, in the details of plate design and the sealing technologies used. These high-quality exchangers are built for maximum performance and longevity in mind with a thicker gauge 316L stainless steel and the plates further apart to prevent debris clotting for much longer life. These Dragon plate exchangers are 40% heavier and better made than the competition. The heat exchanger's compact, rugged assembly is composed of stainless steel 316L plate packs sealed & pressed together by means of brazing 99.9% pure copper along the border of the units. This eliminates the need for traditional gaskets or external pressure retaining parts. The plate packs are embossed with special corrugation patterns to promote high turbulence flow, which dramatically increases the heat transfer rates of the units thus making them a highly economical and effective solution for many processes and heating applications. We continue to improve and develop products to optimize our customer's processes. Making AH&S in the forefront on plate heat exchangers.

Specs: Port Size: 1" MPT, Max Temp. 428F, Design Pressure: 435PSIG, Heating Transfer area 2.71SQ.FT, Channel Volume 0.06 Gal

Advantages of Brazed Plate Heat Exchangers: High heat transfer coefficient Small unit size with high heat transfer capacity Cost efficiency Stainless steel connections Easy installation

Typical Applications: Outdoor Wood Boiler, Furnace, Beer Brewing, Radiant, Ice Melt, Central Heating Hydronic Heating Solar and Geothermic Heating Industrial Process Heat Recovery Condensers and Evaporators in Refrigeration Systems Oil Coolers Close Approach Fluid-to-Fluid Heat Transfer

Typical Applications

- Central Heating

- Beer Brewing

- Hydronic Heating

- Solar and Geothermic Heating

- Industrial Process Heat Recovery

- Condensers and Evaporators in Refrigeration Systems

- Oil Coolers

- Close Approach Fluid-to-Fluid Heat Transfer

Performance Data

- BTU Rating: 75,000 (Commonly used for heating 2,500 to 3.000 well-insulated homes).If the home is not well insulated add 10 to 20 plates to compensate for efficiency. Btu Rating is based on 10 GPM; 180F water

- Connection Size: 1" MPT

- Dimensions: 5'' x 12'' x 4.12"

Features

- High heat transfer coefficient

- Small unit size with a high heat transfer capacity

- Cost efficiency

- Stainless steel connections

- Easy installation

Designed for maximum performance, the brazed plate heat exchanger's compact, rugged assembly is composed of stainless steel 316L plate packs sealed & pressed together by means of brazing metal along the border of the units. This eliminates the need for traditional gaskets or external pressure retaining parts. The plate packs are embossed with special corrugation patterns to promote high turbulence flow, which dramatically increases the heat transfer rates of the units thus making them a highly economical and effective solution for many processes and heating applications

Advantages of Brazed Plate Heat Exchangers:

- · High heat transfer coefficient

- · Small unit size with a high heat transfer capacity

- · Cost efficiency

- · Stainless steel connections

- · Easy installation

Typical Applications:

- · Central Heating

- · Beer Brewing

- · Hydronic Heating

- · Solar and Geothermic Heating

- · Industrial Process Heat Recovery

- · Condensers and Evaporators in Refrigeration Systems

- · Oil Coolers

- · Close Approach Fluid-to-Fluid Heat Transfer