How to Fix a Wood Boiler Circulating Pump Step By Step

Posted by SEBASTIAN ZOTA

In this blog post we are going to talk about a seized wood boiler pump. Most of them after 6 years, 8 years or 10 years of usage they start to build up a goop inside the unit, rust, and scale, so you'll find out how to unseize them and continue to use them.

What to Do If Your Wood Boiler Pump is Not Circulating?

So if you notice that your pump is not circulating once you activate the power, turn off the power as soon as you can because you can burn up the head of the unit, and you don't wanna do that, because if it's just a stuck cartridge, you just burnt the head on it so it's just no good.

You don't wanna ever circulate a pump when there's no water in the cartridge, it will immediately blow the cartridge.

Armstrong and Taco have a very good amount of time that they can run without water before it blows the cartridge or overheats it.

What I'm telling you here is about the same on all the other pumps that I've known to possibly fix or repair these things.

So you're getting ready for the season and you turn on your furnace, and you notice there's no water circulating, turn off the power to the pump.

There are four bolts on the base side of this thing, and I've already pre-practiced because I'm sure you don't wanna see me unscrewing bolts for five minutes here.

Fixing a Sized Pump

And you gotta pretend this is mounted to the back of your boiler. You can do this when mounted right at the back of your boiler. You might get some water flow, so again, turn off the ball valves to stop the water coming out.

Removing the Head of the Pump

Ant then what you're gonna do once you’ve taken out the bolts, you're gonna pull the head off.

The Head of the Pump

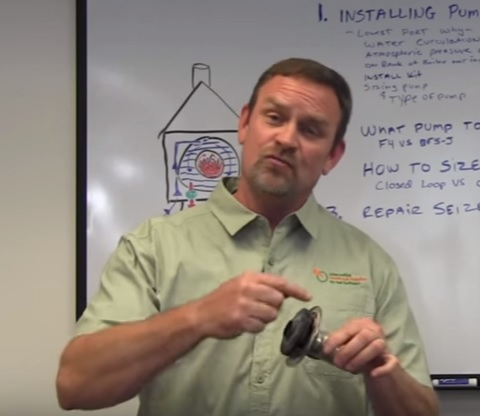

Now, here's the head, here's the other bolt, and here's your cartridge.

The Pump Cartridge

This is actually a pump that is been warrantied by us, but they are moving pumps, they're gonna fail eventually. So in this case, this one didn't last very long. This one pumped in about 6 months, something was out of balance or something wasn't just right when it was made, so they seize very quickly.

Removing the Cartridge

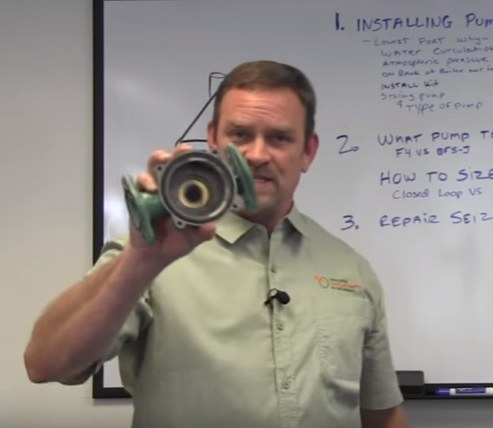

Now, in this case, I already did the seal, so before the thing, is that a lot of time, these cartridges are stuck because they heat up and they get stuck. So you take a screwdriver very gently, and you're just gonna work around, and you're gonna slide the cartridge out.

Removing the cartridge

Now, this is a cartridge, it has nothing to do with the bindings, it's separated from the water, this is in the water. And what happens is the rust and scale build up around the shaft, and it clogs this or sticks it. So what I tell people to do is to take this in, put it on warm water and start spinning this. And you're actually, in this case, this one starts freeing up as I was doing this, and this one's actually probably good, so I might use this my own application, my own stoc. So basically, run around in the nice warm water and try to free this up.

The Cartridge

Now, as you can see this is spinning really nicely now. When I first started with this one, when I first did it, it was barely moving, so the motor didn't have enough energy to spin this up.

The New Cartridge

Now, here's a brand new one, and since these are BF5-Js and BF4-Js, we only sell the brands cartridge once, which will last much longer. Now, as you can see this one moves a little bit easier than the other one. And just so you know, this new one is a cartridge for 0011, and the old one is for a 009, so I know they're different. So this one is smoother, but it doesn't mean that the motor doesn't have enough power to get that started up, it might even start up again.

Now, what I do is that I put it back in, and here, there's a little piece of steel here that is separating, and your old ring is right in here. Make sure that's nice and clean, remount, and there's a sharp edge of the thing, and make sure it's on the inside, and you're not cutting the old ring. And you'll feel it, it just clicks in.

The Pump Ring

And let me tell you one more thing, a lot of people are asking me, "If I mount it like this, you know, that's a problem because of the part where the electricity goes in, and I don't have the room, so can I turn the motor the other way around so that this is out of my way now?" Sure, no problem.

Testing the Pump

Then you put your bolts back, secure it up. And then what I do is I actually just take the electrical lines, and I wire or tie them to a plug and just turn it on. Just plug it in. And if I hear a spinning sound, then I'm ready to go. Test it and if it doesn't spin, then you know that you need a new pump.

But that's really all there is to it. And even on the Armstrong, it's the same concept. They use little irons here, but this is fundamentally the same concept.

The Armstrong Pump

Fixing a Seized Pump FAQs

Another question that I get is "Do the pumps come with the gaskets for the flanges?" The new pumps do come with the gaskets, but that's basically nine out of 10 times that we'll fix your pump, you're ready to go for another season.

The new pumps do come with the gaskets, but that's basically nine out of 10 times that we'll fix your pump, and then you're ready to go for another season.

Let us know if you liked our video and please write your comments on our youtube channel. I would love to hear more suggestions and more areas of focus that you need to know about.

Check out our yearly maintenance kits and do it yourself kits, and if you need assistance or you have questions that we did not cover here, give us a call!