Outdoor Wood Boiler Water Treatment Explained

Posted by JEFFREY LUFF

Water might seem harmless, but inside an outdoor wood boiler, it’s anything but. When left untreated, it can quietly eat away at your system, cause scaling, destroy your gaskets, and reduce your boiler’s lifespan (sometimes by years).

In this post, we’ll walk you through exactly why water treatment matters, what happens when you skip it, how to choose the right product for your system, and how to test and treat your boiler water like a pro.

Why Water Treatment Is Critical for Outdoor Wood Boilers

Let’s start with the basics: untreated water causes damage, plain and simple. Outdoor boilers are often made with steel or stainless steel components that react to oxygen, acidity, and minerals in untreated water. Left unchecked, that can cause:

- Corrosion and scaling in water jackets, heat exchangers, circulating pumps, and pipes

- Shortened system life due to internal rust and sediment buildup

- Leaks around fittings where gaskets and seals start to fail

- Reduced efficiency, meaning you burn more wood for less heat

We’ve seen outdoor boilers with completely seized pumps, rusted-through fittings, and even internal pitting, all because of neglected or incorrect water treatment.

That’s why every heating system we ship or maintain gets set up with proper water treatment right from the start.

What Happens When You Skip Water Treatment

If your boiler’s been running untreated, or only partially treated, here’s what you might notice over time:

- Rust in the water or on your fittings

- Corroded heat exchangers and fireboxes

- Damage to gaskets and seals due to high mineral content

- Rising fuel costs (your system has to work harder to produce the same heat)

Cost Comparison:

- Untreated system with rust damage = hundreds (or thousands) in repairs

- Properly maintained system = minimal cost for treatment and test kits

In short: boiler treatment pays for itself, and then some.

The Essential Components of a Wood Boiler Treatment Plan

pH Balancing

Your water’s pH should ideally fall between 8.0 and 10.5, no more than 11.5. Go too low (acidic), and you’re corroding your system from the inside. Too high (alkaline), and you risk scale buildup that clogs pipes and reduces efficiency.

Oxygen Control

Oxygen is one of the biggest enemies inside any metal system. Once oxygen enters the loop, it begins to corrode metal surfaces, especially in steel and cast iron components.

- Deaeration (removing air from the system) helps, but

- Chemical oxygen scavengers (included in treatments like ProTech300) go further by neutralizing residual oxygen

Corrosion Inhibitors

Corrosion inhibitors are like a protective film inside your system. They line your components and protect against the effects of acidic water, oxygen, and scale-forming minerals.

- Single-metal systems (e.g., all steel) need one type

- Multi-metal systems (steel + brass + copper) need broader-spectrum treatments like AmTech300 or ProTech. Both products can work for any unit.

Recommended Water Treatment Products

We’ve developed, tested and used all of these ourselves, and are made to outperform the treatments provided by other boiler manufacturers.

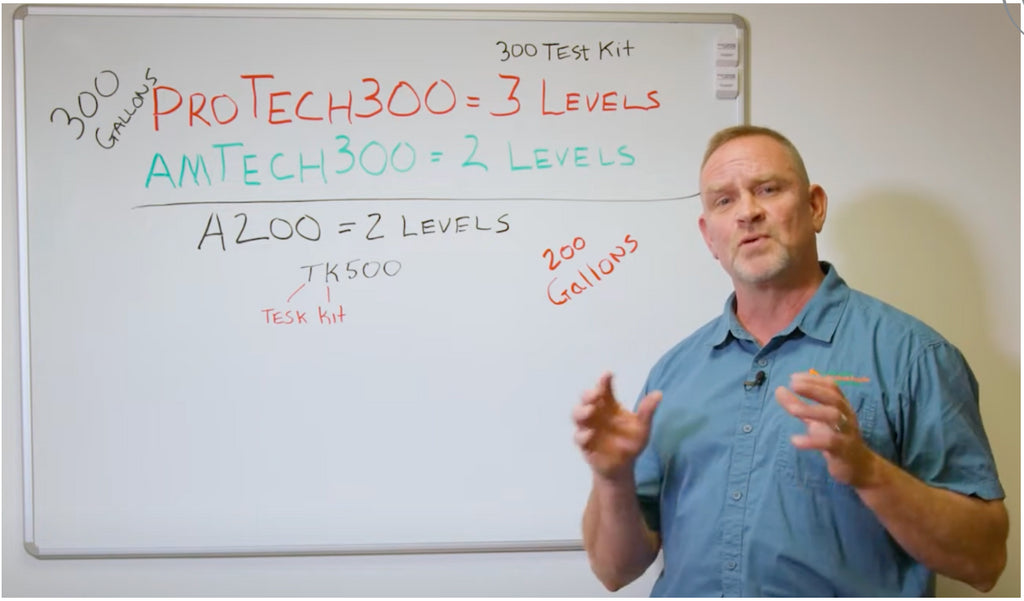

ProTech300

Our top-shelf treatment with three levels of protection, more than any other we’ve found.

- Nitrite-based corrosion inhibitors

- Phosphonates for mineral control

- Built-in pH buffers

- Designed for closed-loop steel or stainless-steel systems

- One gallon treats 300 gallons

- Pair with the 300 Test Kit

Most manufacturers only offer 1 or 2 layers of protection; ProTech300 gives you all three at once.

AmTech300

Perfect for all systems, providing two levels of protection. Get good protection with AmTech, but protect the job great with ProTech.

- Nitrate-based

- Great for indoor and outdoor systems

- Effective in setups with brass or copper components

- Controls mineral deposits and scale

- Also treats up to 300 gallons

- Use with a test kit to monitor

- How to Test and Maintain Your Water Quality

When and How to Test

You don’t have to test weekly, but at least 1x per heating season is a smart habit.

Use a test kit or send a sample to a lab - only necessary if you have a newer central unit boiler with an active warranty.

Check for:

- pH levels

- Nitrite levels

- Total hardness (for mineral issues)

Signs Your System Needs Treatment

- Rusty water

- Poor heating performance

- Gurgling or bubbling sounds in pipes

- Leaks or corrosion spots near fittings

While these signs do tell you when your boiler needs treatment, we recommend being proactive and doing it, regardless of noises or other things. Treating your system at the beginning of the season every year is the best bet. If you see any of these, it’s time to flush and treat.

Step-by-Step: How to Add Treatment

- Flush and clean your system using CF-205 Cleaner

- Determine your system capacity (in gallons)

- Add the correct amount of treatment:

- 1 gal ProTech300 or AmTech300 = 300 gal

- Run your circulator pump to mix it evenly

- Wait 24–48 hours, then test

- Recheck treatment every season or after topping off water

Watch our full in-depth walkthrough on YouTube: Outdoor Boiler Treatment Video

FAQ

How often do I need to add water treatment?

Every 12–24 months, depending on system performance and water testing results.

Can I mix different water treatment products?

If you’re using our water treatments, yes, you can mix different ones. For example, if using AmTech300, you are able to protect without draining. However, if using other brands, we do recommend flushing and cleaning the system before using our products.

What if my water is already filtered or softened?

You still need treatment. Filtered water removes solids, not oxygen or acidity.

Can I use this in systems with PEX or plastic lines?

Yes. All our treatments are compatible with non-metal plumbing, like PEX.

Shop Boiler Water Treatment You Can Trust

We’ve been doing this a long time, and we stand behind every product we sell. Customers tell us all the time that ProTech300 or AmTech300 outperformed what their original manufacturer recommended.

- Trusted by thousands of outdoor boiler owners

- DIY Kits available for complete maintenance

- Test Kits matched to your treatment

- Free shipping on qualifying orders

Protect your investment. Shop our wood boiler treatment products to keep your system running smooth.