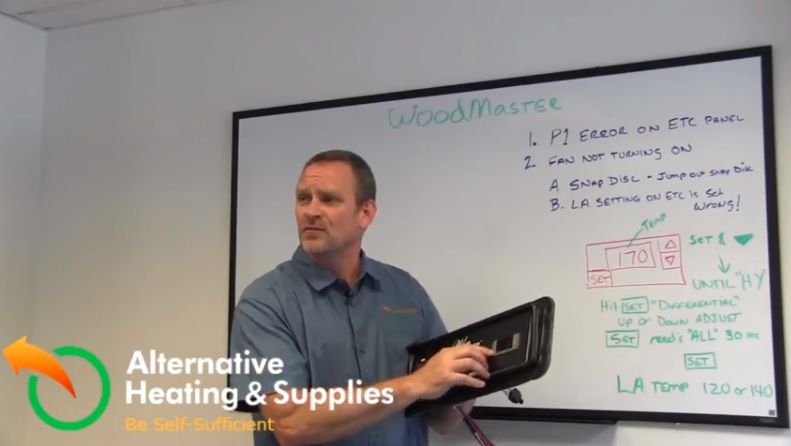

Fixing a WoodMaster Furnace Panel When the Fan is Not Working

Posted by SEBASTIAN ZOTA

This is another Alternative Heating & Supplies episode on how to fix the most common issues displayed on the panel of your wood burning stove. Find out how a wood stove fan works and what prevents it from working well. Learn what a snap disk is, how to reset it, and what other settings are recommended so that your Woodmaster outdoor stoves can run properly.

There are cases in which the outdoor wood boiler controller is on, the temperature is showing 140, let's say, and the fan indicator light on the control panel or the ETC board is showing fans on, but the fans aren't engaging. What can be the problem?

Why is the Wood Stove Fan Not Working

We have two main factors that can cause the wood furnace blower to stop:

- The Reset Function: hit reset or the set button once to reset it and that'll engage it again. Once the stove drops below 140 degrees or so, the stove turns off automatically. It does that because it assumes that it runs out of wood, and therefore it turns off the fans. So, when you come out to the unit and you notice there's no wind in it, hit set is the first thing you do. That should usually just jump start those fans. Put more wood in, you're good to go.

Wood Stove Maintenance: Control Panel Reset

- The snap disc: the snap disc is a little device that sits in the very back of the wood furnace also right above the temperature probe. This one will be about a foot and a half, 18 inches higher, the snap disc, over the temperature probe. Now, these have 110-volt wires running to the back of this one and has two wires, a white and black, disappearing in the insulation which is a spade connector to the snap disc. The snap disc's mission is that if the unit gets over 190 degrees, it activates this and turns off the power. That means the stove is overheating. Something's gone wrong. Therefore, shut down the fan. Shut down everything. That's the purpose of it.

Wood Stove Maintenance: The Snap Disc

How Does a Snap Disc Switch Work

Now, if the snap disc gets triggered and you're not there to see it, a lot of people call me and say, "Hey, my stove's at 155 degrees. The fans aren't turning on," because this doesn't re-engage until about 150 degrees. So the stove has to drop below 150 degrees for the snap disc to deactivate and allow the unit and fans to turn back on.

Let it drop to about 145 before you start considering it if it's a snap disc because a snap disc might not engage. If you think it's a snap disc and you think that's the problem, simple solution is pull off the two spade connectors, put a jumper wire between those two, and that bypasses the snap disc. And if the fans turn on, you know it's a snap disc. Okay? Snap discs are very cheap and they can go bad. Simple fix, a couple of screws into the back of steel spade connection, hook it back up, you're done.

The Snap Disk Fan Control

Now, some of the newer WoodMasters use two of these. One is where I just described, in the back disappearing in insulation, and there's another one that's jumped off of this one to the back rear fan of the larger unit, the 5500. The snap disc mounts on the intake by the fan in the back of the unit. And that's to prevent that if the fan in the back stopped working, the air blowing through the back won't burn up the back of the fan. So if the fan stops spinning, that protects the fan in the back. So there's two of these on the newer 55's, okay?But if you bypass this one, you bypass that other one on the 5500. So just look at that. It's all it does, okay? It's a simple solution.

Wood Stove Fan Still Not Working?

Now, if none of the two problems discussed above can fix the wood stove fan issues, the only other thing it can be is the control panel settings and programming. This is a big problem as a lot of people want to see what the stove can do, what kind of settings are in here, and how to program it, and they can mess up the settings.

Wood Stove Control Panel Settings

The basic things that you should be messing with the control panel is if the temperature increases outside, you wanna bring the temperature of the boiler down. So if it becomes 50 or 60 degrees, you wanna bring the temperature, not from 180, you wanna bring it down to 170 or 160. Nothing lower than 150

How Do You Bring the Temp Water Temperatures Down?

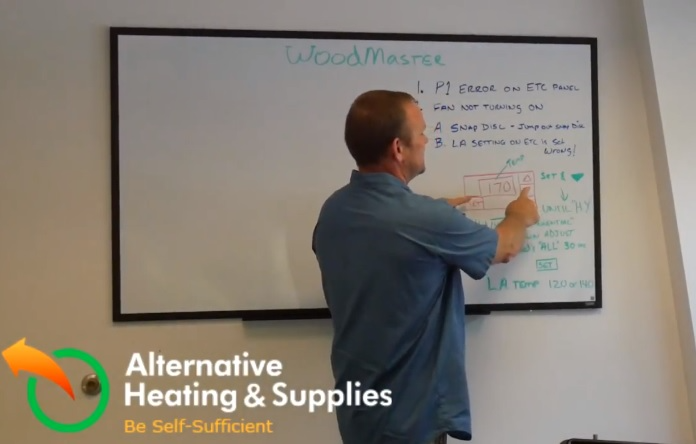

Here is a simple picture that I've drawn here of the control panel. In this case, you just hit the set button for three seconds, and when that happens, the temperature of the water goes away.

Resetting the Control Panel

So let's say the temperature is at 178. If I hit the set button for three seconds, the 170 value shows up. That means my furnace is set to engage at 170 degrees. So when I do that it'll show the temperature of the set point, and then, use the up or down arrow to set it, hit the set button one more time and then it'll flash three times. Let's say, you'd bring it up to 175, it'll flash three times, letting you know it's set for 175. Then, it returns to the water temperature inside the boiler.

The HY Setting

Now, what people do is they start messing around with the other settings that are deeper in the control panel. These control panels were designed to run for duration systems and all sorts of other things, and they have a lot of settings. But the most common problem is that people start messing with the Hy and the ALL settings.

And how do you get to them? I’ll show you in the picture here.

The HY and ALL Control Panel Settings

To get to the Hy setting you'll have to hit the set button and the down arrow for a period of time. Then what will happen, where the temperature comes up, the Hy emblem will show up.

The Differential Setting

Now, if you hit the set button one more time, the differential setting appears indicating the range values the stove turns on and off.

So if it's five, that means that it has a five-degree differential. If it's set to 170, that means the stove will turn on at 165 and turn off at 170. That's the five-degree differential. If you had a ten-degree differential, that means the stove will turn on at 160 and turn off at 170.

You can adjust your differential anywhere from 5 to 15 to 20 degrees. I do not recommend 20 or 15. My two favorite numbers are 5 and 10. From the factory, it comes set up to a 10 degrees differential.

The ALL Setting

So you set your differential. And then again, to lock it in, you hit the set button again, and it will flash. And what'll happen then, it will read it ALL. Now, you don't mess with it if that's all you're playing with at this point. But what people do is they start messing with the ALL. So if you wanna set your differential, hit the set button and wait 30 seconds out. And you'll see "ALL". Wait 30 seconds and it'll go back to the temperature, and you're done. Stop right there.

The LA Setting

However, if you decide to mess with the differential and you hit set and it goes to ALL, and you hit set but one more time, it goes into a low-temperature alarm or LA. Now, LA, you'll probably see it on your WindMasters and that means "low alarm".

What that means and in what they're originally set for is that when people have refrigeration systems they will have a leave-a-door-open and the low alarm will be set. And it sets off an alarm for the refrigeration systems. But what the low alarm is doing for us is that it shuts off the unit.

Now, a lot of people bump that up to 160 or 170, which kind of defeats this temperature that it's set to, so the unit and the fans never turn on. So once you get to ALL, you hit set, and the low alarm will come on. That will just show a number. Get it down to 120 or 140, that is telling you that the only time that low-alarm will engage is when that temperature of that water in that boiler is 120 or 140 degrees. That means you've run out of wood and to shut it off. Shut off the boiler and the fans.

That's basically it for the WoodMaster and the problems that it could be. If there's something else besides that, you've gotta look at your fans or your solenoids or anything that is short. But besides that, there's really not much that can go wrong with the WoodMaster. It's a very good product. It's very simple and easy.

If you need help, you can always call us at Alternative Heating and Supplies, and we'll be glad to assist you.

Check out our new website, we're advertising a lot of wood boiler brands and wood stove accessories, because the industry is being hurt by the new EPA regulations but hopefully, they'll be going away soon.